SMD Heat Sinks in Electronic Circuits

SMD heat sinks dissipate heat to prevent component failure, enhance reliability, and support compact designs, essential for modern, high-performance electronics.

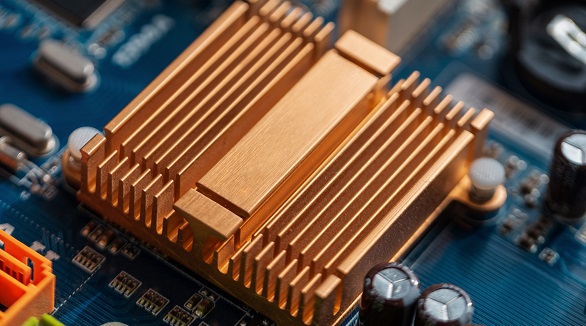

In the context of electronic circuit design, efficient thermal management plays a crucial role in guaranteeing the longevity and reliability of electronic components. SMD heat sinks play a critical role in this, providing a vital channel for thermal dissipation established by electronic components. With technology compacting functionality into smaller form factors, the significance of SMD heat sinks increases towards maximum performance and reliability.

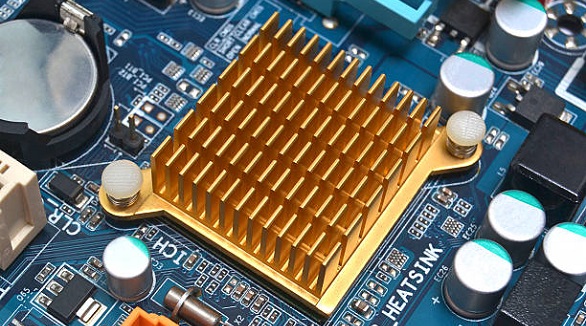

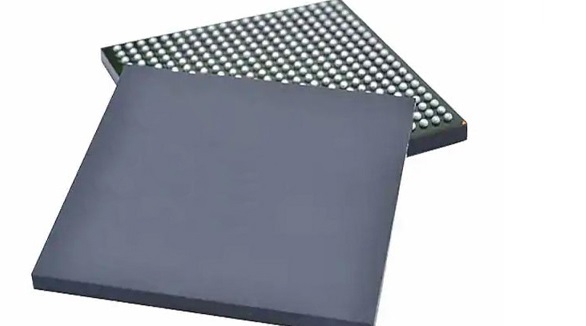

An SMD heat sink is employed to dissipate and absorb heat produced by power devices such as power transistors, LEDs, and processors. The heat sinks radiate heat from the device to some other part of the circuit where it can be dissipated more easily, thus preventing heat buildup that results in early component failure. This includes thermal routing design principles, such as in the electrical routing based on the utilization of conductive material, enough surface area, and vias to provide for the heat flux from its source.

Significance of SMD Heat Sinks

Prevention of Overheating

Overheating can be contributed significantly by failure among electronic components. SMD heat sinks provide excessive heat dissipation to maintain components in safe temperatures for use, preventing potential instantaneous and unreparable damage.

Enhancing Component Reliability

By maintaining components in ideal temperatures, SMD heat sinks extend the operational lifespan of a device. Thermal management helps minimize thermal stress, hence ensuring devices stay stable over time without decaying.

Enabling Compact Design

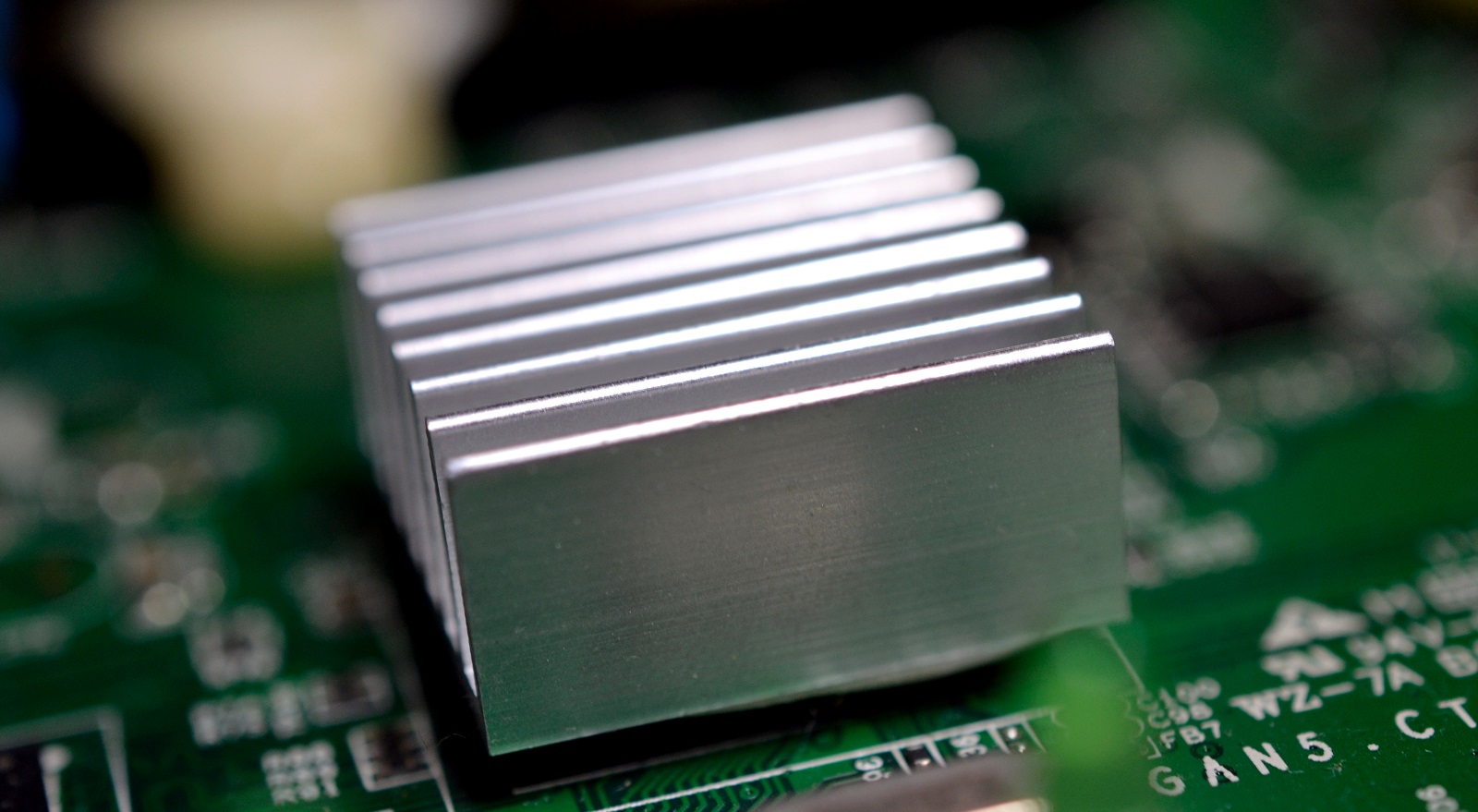

As devices continue to shrink, heat dissipation becomes more and more challenging to manage. SMD heat sinks are an extremely effective solution to such problems without adding much bulk, which is precisely in tune with the miniaturization trend of modern electronics.

Cost-Effective Thermal Management

Built using light and cheap materials such as aluminum or copper, SMD heat sinks are an economical way of managing thermal profiles. They enable high thermal conductivity without the addition of weight or cost to the system.

Mounting SMD Heat Sinks

Mounting SMD heat sinks involves some methods to achieve maximum thermal conduction:

Direct Attachment to Components: Mounting heat sinks directly onto the component package helps in maximizing heat dissipation.

Application of Thermal Pads or Compounds: Thermal greases or pads may be used to improve the thermal bond between the heat sink and the component to enable improved heat flow.

Bridging Heat to Enclosures: Heat sinks in some configurations act as bridges, transferring heat from individual components to the device enclosure as a whole or into designated heat-dissipating components.

Understand and apply proper mounting procedures to maximize the effectiveness of a heat sink in thermal management.

Selecting the Proper SMD Heat Sink

When applying SMD heat sinks to a design, the following should be taken into consideration:

Thermal Specifications

Define the thermal design point of the PCB components. Knowing the power dissipation requirements and optimal operating temperatures helps determine the level of thermal management required.

Space Issues

Compute usable space in your PCB layout to fit the heat sink. Because the shape and size of heat sinks differ, it is essential to have one that accommodates the spatial constraint of your design without interfering with other components.

Material and Design Features

Examine the physical characteristics—weight, price, and thermal conductivity—of the material and dimension requirements of the heat sink. Choosing proper material and design is essential in order to achieve effective heat dissipation.

Mounting Methodology

Think about if a mechanical or non-mechanical attachment method is appropriate for your design. The method selected should be congruent with the features of the heat sink as well as with the needs of the board.

Benefits of SMD Heat Sinks

Using SMD heat sinks in electronic circuits has many important advantages:

Thermal Control: SMD heat sinks help to greatly increase the thermal control abilities of a PCB design to effectively counter cooling and heat dissipation issues.

Improved Lifespan: Through effective thermal management, SMD heat sinks not only prolong the lifespan of components but also reduce the requirement for replacement periodically.

Economic: SMD heat sinks are economical as they are cheap and therefore provide an affordable alternative to thermal management, particularly where costs are involved.

Lightweight and Economical: Made with materials such as aluminum and copper, SMD heat sinks are able to transfer heat effectively without adding to excess weight in design.

SMD heat sinks are a critical part of modern electronic circuit design, easily eliminating thermal problems that threaten component reliability and performance. Adding SMD heat sinks to your PCB designs helps you shield your components from excessive heat, extends the life of your components, and enhances device reliability. These small devices truly come through where the demand for handling heat in compact, high-performance electronic designs is at stake.

Our expertise in designing and assembling PCBs at PCBX includes high-quality thermal management solutions like SMD heat sinks in our product line to ensure that your products achieve the optimal level of performance and reliability. With our capabilities and precision in mounting SMD heat sinks, we are capable of helping you create electronic designs that do not only work fine even in unfavorable conditions but also stand the test of time within the corporate environment.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Heat sinks are essential for reliable PCB design, managing heat in high-density components like transistors and LEDs, ensuring optimal performance.

Populated circuit boards integrate electronic components for efficiency and reliability, utilizing SMT and THT for diverse applications across industries.

Compared to THT, SMT offers better miniaturization and weight reduction in any electronic application. With the use of BGA packages, high-assembly density, reliability, and improved performance are achieved; on the other hand, this requires a rework and inspection that is not really common. PCBX specializes in the area of advanced SMT and BGA assembly to help drive modern requirements of compact electronic devices.